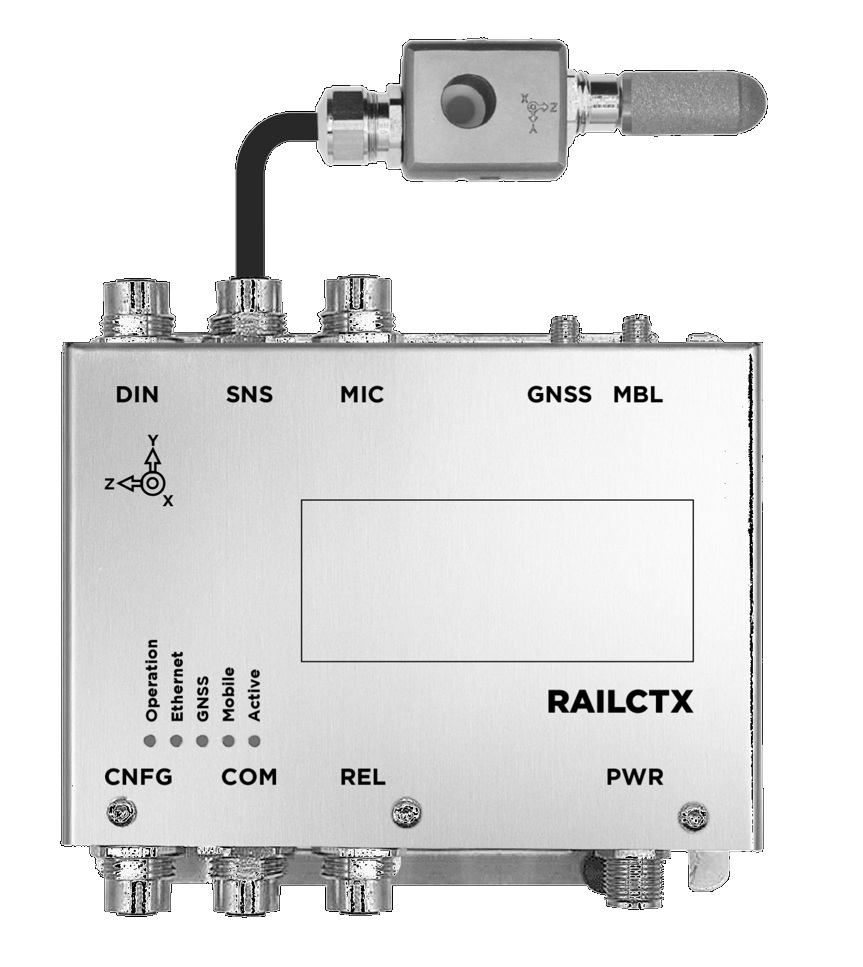

RAILCTX - Measurement and control device

Intelligent measurement and control in operational use

RAILCTX is an edge platform for detecting and processing physical events in railway operations.

The devices record vibrations, shocks, acoustics, and environmental conditions at critical points on vehicles and infrastructure and evaluate these signals directly on site. Unlike pure measurement systems, railCTX does not deliver raw data streams, but rather pre-processed features that can be used immediately for operations:

- With local deterministic logic

- In the cloud or

- As a data streamer in combination with MEC AI Edge computers.

railCTX can be trained with the RET (Rail Efficiency Toolkit): High-resolution measurement campaigns with RET are used to derive relevant thresholds, patterns, and rules, which RAILCTX then reliably monitors in continuous operation.

Typical applications

- Early detection of abnormal wheel-rail interactions

- Early detection of noise

- Detection of unusual contacts, impacts, or vibration patterns.

- Monitoring of critical infrastructure points

- Condition-based event detection at switches, crossings, or bridges.

- Analysis of characteristic noises to identify wear or faults.

- Incident detection with evidence

- Real-time detection of events with traceable data as a basis for decision-making.

- Local response and control

- Digital inputs and outputs enable triggers, warnings, or operational measures directly in the field.

railCTX operationalizes physical reality in railway operations—through local event detection, reliable evidence, and scalable edge integration.

RAILCTX with ACS acceleration/shock sensor

RAILCTX-E (IP67, internal microphones)

Technical Specifications

- EN50155 / EN45545 / CRA Compliant

- IP40 (RAILCTX) / IP67 (RAILCTX-E)

- 3 internal microphones with interchangeable membrane (RAILCTX-E)

- Multidimensional motion detection (IMU) – acceleration, vibration, impact, angular acceleration

- Acoustic sensors

- Environmental context (temperature, humidity, pressure)

- Local preprocessing and event detection

- Deterministic control logic or AI-based classification

- Highly available LTE communication with dual SIM

- Optional edge streaming to MEC systems

- Cloud connection for comparability, reporting, and alerting

- External bus sensor connections

- Digital inputs and outputs for local actuators

- Integrated position determination (GPS optional)

Why choose MOVCTX?

- Early detection instead of damage – Detects mechanical stress before it leads to failures.

- Clear event documentation – Incidents are automatically detected and stored with a time stamp.

- Intelligent evaluation in the device – Relevant events instead of unnecessary raw data.

- Optimized for distributed systems - LoRaWAN-ready for vehicles, fleets, and infrastructure.

- Precisely calibratable - Can be trained with the RET measurement system for high-precision applications.

📩 Talk to us about your application—we'll show you how MOVCTX reliably secures your vehicles and infrastructure.